PCAO – P-Based Cognitive Adaptive Optimization

One of the main reasons for the limited deployment of control systems to complex, real-life Large-Scale Systems (LSS) and especially to Systems of Systems (SoS) and Large-Scale Cyber-Physical Systems (LS-CPS) is the inability of conventional control methodologies to provide efficient control designs for such systems. Existing control designs typically require an “expensive” and consuming initial design phase as well as constant calibration and re-configuration of the control system throughout its lifetime. PCAO (developed in the project AGILE, www.agile-fp7.eu) presents itself as a generic control design tool that overcomes these shortcomings. Such a generic tool can be implemented via three different ways:

- As a model-based control design tool: In case a model for the LSS dynamics is available, the PCAO control design can be used to provide an efficient control design based on this model, no matter how elaborate or complex is the LSS. Based on many comparative simulations we experienced that, the PCAO control design accomplishes the control design extremely fast, while well-established state-of-the-art approaches totally fail due to the large-scale and complexity of the problem. Moreover, the PCAO control design tool is of “plug-n-play” nature: all has to be done is to just plug the PCAO control design tool to the LSS model without requiring any tedious preparatory analysis, interfacing, etc.

- As an automated fine-tuning tool: In case the LSS already implements a control policy, the PCAO control design tool can be used as an automated fine-tuning tool that on-line tunes (optimizes) the control law while operating in the LSS. The vast majority of practical LSS control systems (e.g., for energy or traffic management) requires a fine-tuning procedure, which is typically taken care by teams of highly experienced personnel: such a manual-based tuning phase can be extremely time- and effort consuming and, due to the complexity of the system, there is no guarantee that it will be successful. The use of PCAO automated fine-tuning tool not only neglects the requirement for employing highly experienced personnel but, most importantly, it guarantees that the tuning procedure will be extremely successful.

- As a model-free control design tool: In many cases, because of the complexity of the LSS system, there is no availability of a model which satisfactorily describes the LSS dynamics. Consequently, no model-based control design can be performed by the designer. PCAO can provide with efficient and robust control design even in cases where a very poor of even no model for the LSS dynamics is available. By employing its intrinsic self-adaptation mechanisms, PCAO can rapidly and efficient learn optimal control policies without using any knowledge of the LSS system dynamics. This is contrary to state-of-the-art methodologies where embedding adaptation may lead to severe performance problems, even in cases of small-scale systems.

Part 1: Model-Based (Simulation-based) Control Design for Complex, Large-Scale Real-Life Systems

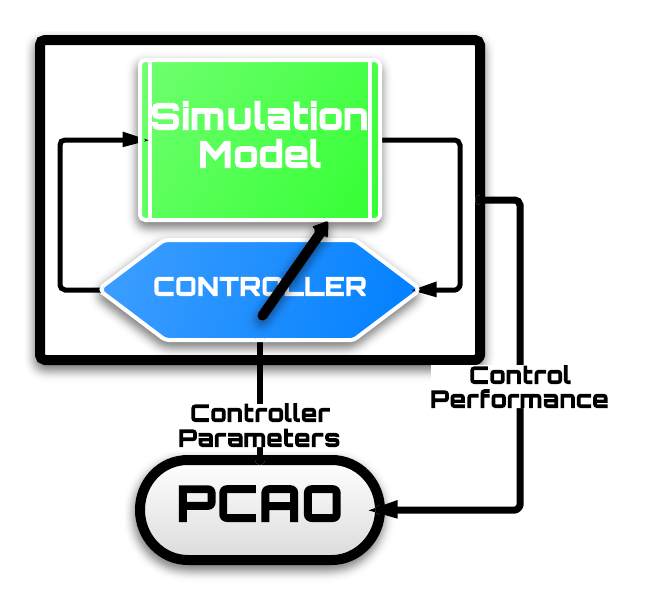

Figure 1. Model-Based (Simulation-based) Control Design architecture.

Recently, there has been a growing interest for simulation-based control design (co-simulation) which can tremendously reduce the effort and time required for the design and deployment of control systems. Unfortunately, existing simulation-based approaches are not able to efficiently handle systems of large-scale nature. Within PCAO, a new simulation-based control design approach has been developed that overcomes such a shortcoming by being able to rapidly and efficiently handle complex, real-life LSS. Successful implementation of the PCAO system to a variety of large-scale real-life applications, including traffic systems and energy efficient buildings, exhibits the powerfulness of the approach to serve as a “plug-n-play” control design tool for real-life systems that may be large-scale, complex and of high heterogeneity. The PCAO simulation-based control design has been tested on many different benchmark large-scale system examples and was compared to state-of-the-art approaches that employ popular optimization algorithms. The results of the comparison are summarized in the next Table.

Simulation-based Control Design: PCAO vs. State-of-the-Art

Approaches(Evaluation Based on Simulation Experiments)

Test Case: Energy Efficient Buildings (2 different large-scale office buildings)

| Simulation-based Control Design Methodology | Iterations | Improvement with respect to the Base Case | ||||

| PCAO | ~50 | 10-30% | ||||

| Popular Global Optimization Algorithms (fmincon, pattern search, genetic algorithms, etc) | >10000 | 0% | ||||

|

Test Case: Traffic Control |

| Simulation-based Control Design Methodology | Iterations | Improvement with respect to the Base Case | ||||

| PCAO | 100-300 | 30-40% | ||||

| Popular Global Optimization Algorithms (fmincon, pattern search, genetic algorithms, etc) | >10000 | 0% | ||||

|

Similar results have been obtained in other Large-Scale Test Cases such as Smart Grids and Computer Networks |

Simulation-based Control Design: PCAO vs. State-of-the-Art

Approacheshes(Evaluation Based on Real-Life Experiments)Test Case:

Energy Efficient Buildings (FIBP Building)

| Simulation-based Control Design Methodology | Iterations | Improvement with respect to the Base Case | ||||

| PCAO | 100-300 | 50% | ||||

| Popular Global Optimization Algorithms (fmincon, pattern search, genetic algorithms, etc) | >10000 | N/A | ||||

Part 2: Automated Fine-Tuning Control Design Complex, Large-Scale Real-Life Systems

Currently, a tremendous amount of human effort and time is spent for the calibration (tuning) of the operations of control systems for real-life LSS. The fact that the vast majority of practical LSS control systems are based on over-simplified models of the LSS dynamics or even on heuristics and “rules of thumb” call for an intensive fine-tuning procedure aiming at optimizing the LSS performance. Besides, such a fine-tuning procedure must act continuously so as to adapt to medium- or long-term variations and changes in the LSS. Typically, such a procedure is taken place by experienced personnel based on field observations via experimentation with different combinations of controller parameters, without the use of any systematic approach. Urban and motorway traffic networks, large chemical processes, sensor networks, advanced computer networks, power networks, Mega City power, water and communication networks are specific examples of large-scale, geographically distributed processes that call for a tedious fine-tuning procedure for the calibration of their parameters, whose number may range from dozens to several hundred or more. Such a fine-tuning procedure may take months, or, in extreme cases, even years, until the control system actually reaches the desired performance. In most cases this procedure may lead to an acceptable, but not necessarily optimal, control behavior, while the need for frequent updates calls for a quasi-continuous effort with all related technical and organizational (e.g. change of personnel) risks. In some known cases the outlined procedure has even led to a complete failure, i.e., the use of the control system was abandoned after the initial deployment due to the failure of the fine-tuning process to achieve a satisfactory performance.

Figure 2. Automated Fine-Tuning Control Design architecture.

The PCAO control design tool can be employed in order to provide with a fully-automated tool for calibrating arbitrary practical control systems. The fully-automated nature of such a tool not only leads to neglecting the need – and all associated risks – for employing experienced personnel but, most importantly, it provides with a guaranteed highly efficient fine-tuning procedure: the application of the PCAO automated fine-tuning tool guarantees not only that the fine-tuning procedure will end-up providing significant improvements but it also guarantees safe and efficient transient performance of the overall fine-tuning procedure. The next Table exhibits the improvements obtained after using the PCAO automated fine-tuning tool in the PCAO Traffic Test Case.

PCAO Automated Fine-Tuning Control

(Evaluation Based on Real-Life Experiments)

Test Case: Urban Traffic Control (City of Chania, Greece)

| Automated Fine-Tuning Control Design Methodology | Iterations | Improvement with respect to the Base Case | ||||

| PCAO | 2-3 months | 30-50% | ||||

The Base Case corresponds to one of the “best” systems used today. PCAO exhibits “good” performance even from the first days. No “poor” transients are observed even in cases of large exogenous factors variations or in the cases where minor or medium incidents are present.

Part 3: Model-Free Control Design Complex, Large-Scale Real-Life Systems

Most importantly, PCAO can provide with efficient and robust control design even in cases where a very poor of even no model for the LSS dynamics is available. By employing its intrinsic self-adaptation mechanisms, PCAO can rapidly provide a very efficient control design. This is contrary to state-of-the-art methodologies where embedding adaptation may lead to severe performance problems, even in cases of small-scale systems.

Figure 3. Model-Free Control Design architecture.

Extensive Real-Life Experiments in the Validation Case (the Maintenance Building of Technical University of Crete, Chania, Greece) exhibit that the PCAO system can lead to significant energy savings (while maintaining user comfort) over the “best practice”.

The next Tables summarize the findings of the experiments:

PCAO Model-free Control Design

(Evaluation Based on Real-Life Experiments)

Test Case: Energy Efficient Building Control (Maintenance Building of Technical University of Crete, Chania, Greece)

| %Improvements | |||

| Model Based PCAO vs Best Practice | ~5% | ||

| Model Free PCAO vs Best PracticeModel Free PCAO exhibits “good” performance even from the very first few first hours of its implementation. No “poor” transients are observed. Also robustness with respect to weather forecasts inaccuracies as well as to sensor faults is one of the key attributes of Model Free PCAO | >20% | ||

What is really interesting is that the model-free PCAO control exhibits significantly better performance than the simulation-based (model based) PCAO. The reason for this is that is that simulation-based control design is “sensitive” to simulation model inaccuracies, while model-free PCAO does have to rely on any simulation or other model.

For more details please kindly refer to http://www.agile-fp7.eu/