AFCON Automation and Control Ltd

The research leading to these results has been partially funded by the European Commission FP7-ICT-5-3.5, Engineering of Networked Monitoring and Control Systems, under the contract #257806 AGILE

Test Case Description:

A commercial building (occupied by 650 employees in average), comprised of 5 floors was selected for Automated Fine-Tuning CAO (AFT-CAO). The test case building, built in 2004, is located in the suburbs (32°06’35.0″N 34°53’12.9″E) of the city of Tel-Aviv within AFCON Automation and Control Ltd. premises; Israel is considered a large-scale commercial building. Floors 1 and 2 are used as storage spaces without any air conditioning units, while floors 3, 4 and 5 are consisted of offices (about 70 offices and rooms per floor), is implemented for the BOC design. The subject building falls under the category of heavy weight buildings with well insulated external walls and large intermediate concrete volumes. Furthermore the building presents glass façades larger than 3m2 in every office.

Some other features of the building:

- The net heated floor area (3rd, 4th and 5th floor in total) is around 2350 m². The annual energy demand is approximately 342.65 MWh or 145 kWh/m².

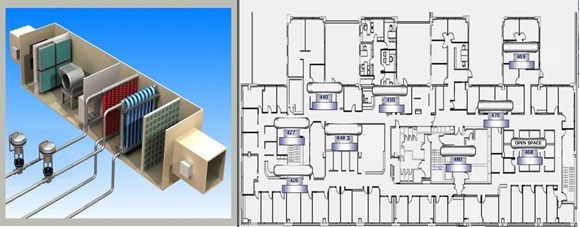

- The building has two couples of chillers; each of the chiller can deliver up to 150 refrigeration tons (total of 600 tons) which corresponds to 527kW per chiller (total 2.108 MW) (see Figure 2a). For maintenance reasons, each chiller of the couple starts as the master chiller every month. So at every given time instant two of the chillers (from different couples) are available for operation. Each chiller is operated independently through a set point deciding the lowest allowed level of the returning water temperature. If the returning water temperature set point is under-passed, the respective chiller is activated.

- The air-conditioning system includes an AHU (Air Handling Unit) per group of offices located on the same floor – in average 10 offices (of about 10 m2 each – equipped, in average, with 3 double glass windows of 5mm gap) share the same AHU for climating purposes (see for example Figure 2b). AHU thermostats, with constant set point 22 ºC (manual thermostat control by the user is available too) are used for the activation of the AHU air-fans in every office, while the valve-tab position is always set to the maximum available setting whenever fan operation is active. Therefore the valves are operated using a simple if-then-else rule which energizes the water flow only when the fans are active (i.e. the respective zone temperature is below the thermostat set point – thermostat operation bounds between 15 ºC and 30 ºC). The AHU is timely operated units, according to predefined schedule timing for working days, weekends and holidays.

- A huge data-base of real life measurement data is available for this building.

Cost Function:

The used cost function considers energy consumption and the level of comfort:

![]()

where 0 < t < 1 regulates the importance of one term with respect to the other. The ![]() is derived by reading the actual real-time power [kW] consumed by each respective chiller. The

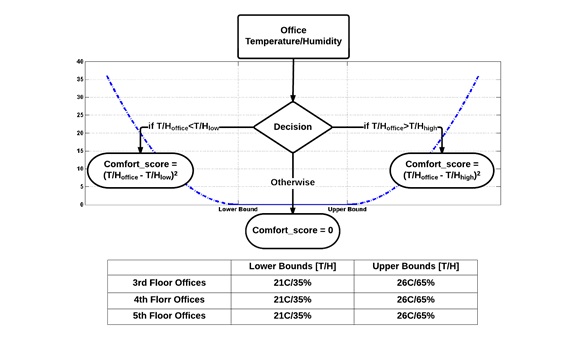

is derived by reading the actual real-time power [kW] consumed by each respective chiller. The ![]() is the user comfort index discussed before defined as a temperature penalizing paraboloid with a user defined temperature satisfying area. The lower and upper bounds for the temperatures were chosen according to occupants preferences as shown.

is the user comfort index discussed before defined as a temperature penalizing paraboloid with a user defined temperature satisfying area. The lower and upper bounds for the temperatures were chosen according to occupants preferences as shown.

Finally in order to establish an even more elaborate and detailed ![]() design, a filtering scheme was adopted so as to take into account comfort score values only during working days and periods [7:00 – 18:00] only for the office rooms (occupancy was considered always active in the server room since valuable infrastructure and machines demanded efficient climating in a constant basis).

design, a filtering scheme was adopted so as to take into account comfort score values only during working days and periods [7:00 – 18:00] only for the office rooms (occupancy was considered always active in the server room since valuable infrastructure and machines demanded efficient climating in a constant basis).

Real-Life Results:

Experiments took place during Monday 30/3/2015 – Friday 10/4/2015. Note that the comparison performance benchmark (Base Case Scenario – BCS) used for comparison purposes is the common rule-based control practice adopted in the real-life building. The BCS control data were extracted from building database during Monday 31/3/2014 – Friday 11/4/2014. It has to be underlined that the internal daily mean temperature during working period, for both AFT-CAO and BCS, was always close to 22°C in all offices (all offices had the same constant thermostat settings in all experiments). In other words, the internal comfort levels were pretty much the same between AFT-CAO and BCS control application approaches, achieving acceptable comfort levels in both cases.

Automated Fine-Tuning CAO proved to be able to exploit the current weather conditions, operating the available chillers in a more power efficient manner in total. Different importance factors 0<t

| Weight Exchange Factor (a) | Total Fair Comparison Index CAO/BCS/Improvement[%] | Total Power [MW] CAO/BCS/Improvement[%] |

| 0.9 | 6.01/10.66/+43.56 | |

| 0.7 | 6.26/9.96/+37.11 | |

| 0.5 | 6.52/9.27/+29.69 | 94.07/171.02/+45 |

| 0.3 | 6.77/8.57/+21.07 | |

| 0.1 | 7.02/7.88/+10.94 |

Real-life experiments demonstrate the intelligence pattern followed by AFT-CAO in exploiting solar radiation and ambient temperature conditions – which affect the efficiency of the available HVACs – through delicate operation of the respective set points, deciding when to activate, when to deactivate and for how long to activate the chillers so as to guarantee reduced energy consumption over a large time horizon, realized even after few days of operation. It has to be underlined that, such delicate control behavior cannot be realized by employing rule-based or constant set point control logic – since power efficiency of the HVACs is heavily dependent on the ambient temperature while indoor building dynamics depend heavily on solar radiation gains – used in the Israeli building as well as in the vast majority of BOC systems today.

AFT-CAO achieves energy savings in the range of 45% with respect to the former real-life control practise